Computer Numerical Control (CNC) machining has become a cornerstone in modern manufacturing, offering precision, repeatability, and speed that traditional methods simply cannot match. From aerospace components to custom automotive parts, CNC machining plays an integral role in achieving high-quality production across a wide range of industries. By digitally controlling machine tools through pre-programmed software, manufacturers can produce complex shapes and intricate details with minimal human intervention.

One of the core advantages of CNC machining is its ability to produce consistent results. Once a part is programmed into the system, that design can be replicated countless times with the same level of accuracy. This is crucial for industries that require tight tolerances and reliable performance. Additionally, CNC machines can operate continuously, significantly cutting down on production time and increasing overall efficiency.

The versatility of CNC machining extends beyond just repeatability. It can work with a variety of materials including metals, plastics, wood, and composites. This flexibility makes it suitable for both prototyping and full-scale production. Whether it’s creating a one-off custom component or running a high-volume batch, CNC machining adapts to the needs of the project. Because of this adaptability, businesses are increasingly relying on advanced cnc machining services to stay competitive in a fast-paced market.

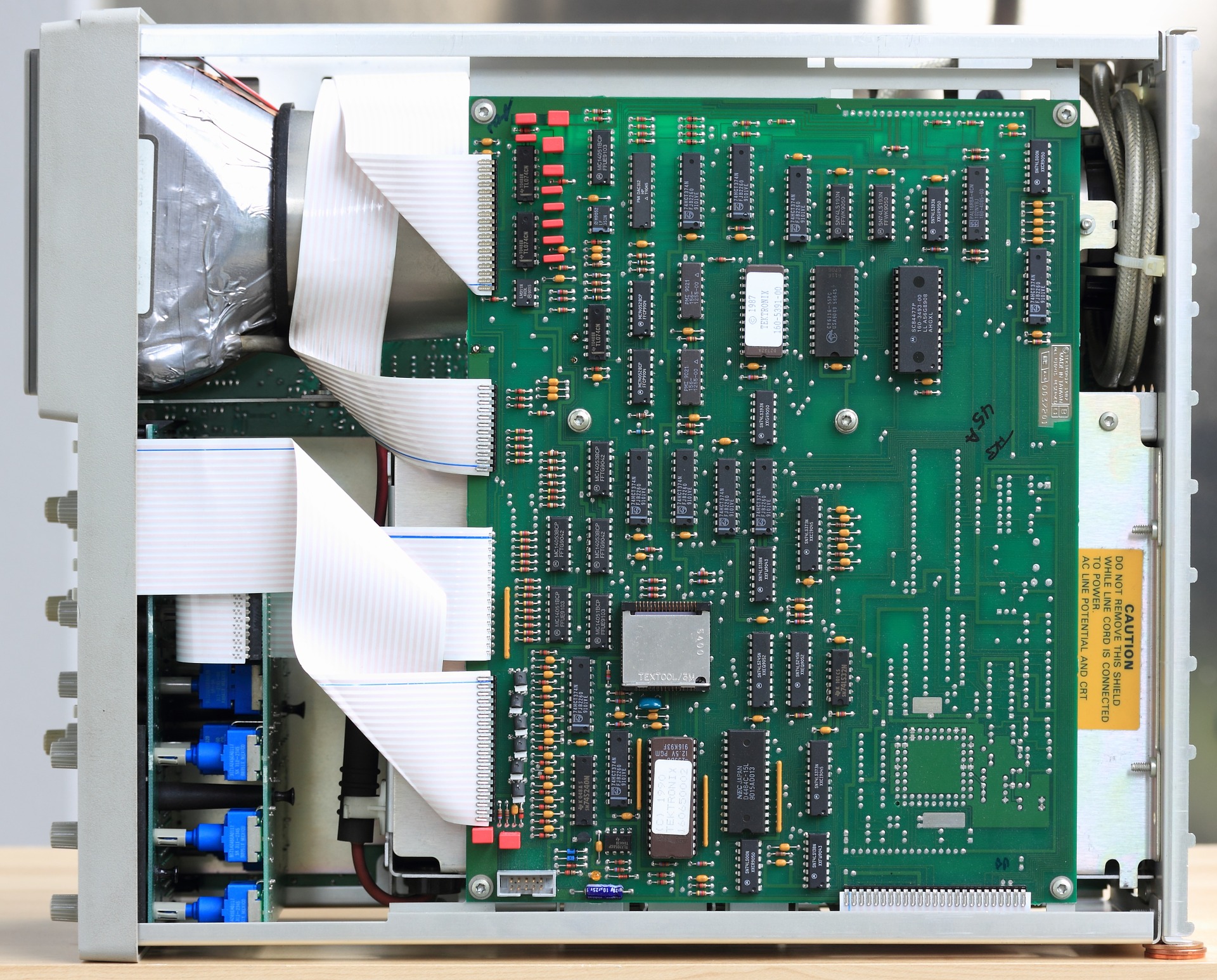

The process itself involves several steps, beginning with computer-aided design (CAD) software where engineers create a digital model of the part. This design is then converted into a computer-aided manufacturing (CAM) file, which guides the CNC machine’s movements. These instructions direct the machine’s tools—such as drills, lathes, or mills—on how to shape the raw material. The resulting product is a precise physical representation of the original digital design.

Another essential aspect of CNC machining is its contribution to reducing waste and optimizing material usage. Traditional methods often involve more manual labor and a higher margin for error, which can result in discarded materials and increased costs. In contrast, CNC machining minimizes mistakes by following exact specifications, helping businesses reduce overhead and environmental impact. This level of control also makes it easier to implement sustainable practices within the manufacturing process.

As technology evolves, CNC machining continues to integrate with other innovations. The rise of smart factories and Industry 4.0 means that CNC machines can now be connected to networks for real-time monitoring and data analysis. This connectivity allows manufacturers to predict maintenance needs, track performance metrics, and streamline workflows, all of which lead to improved productivity and reduced downtime. These advancements are shaping the future of how products are made and how facilities are managed.

Additionally, the growing demand for customized and small-batch products has made CNC machining more relevant than ever. Consumers and businesses alike are seeking tailored solutions, whether it’s in healthcare equipment, electronics, or architectural components. CNC technology supports this trend by enabling rapid design changes without extensive retooling. This agility is a valuable asset in markets that demand responsiveness and innovation.

For companies looking to expand their manufacturing capabilities, partnering with specialized providers can offer significant advantages. Working with experts who understand the intricacies of CNC technology can help ensure that each project meets its quality and timeline goals. It also allows businesses to focus on their core competencies while outsourcing complex production tasks to professionals who have the tools and experience to deliver precision results.

To explore how this technology can enhance your operations, you can learn more by visiting manufacturing solutions tailored to your needs. The integration of CNC machining into your production pipeline could be the step that sets your business apart in a competitive landscape.

As the manufacturing industry continues to evolve, CNC machining remains a vital tool for achieving excellence in both product quality and operational efficiency. Its ability to adapt to diverse applications, combined with technological advancements, ensures that it will remain at the forefront of industrial innovation for years to come.