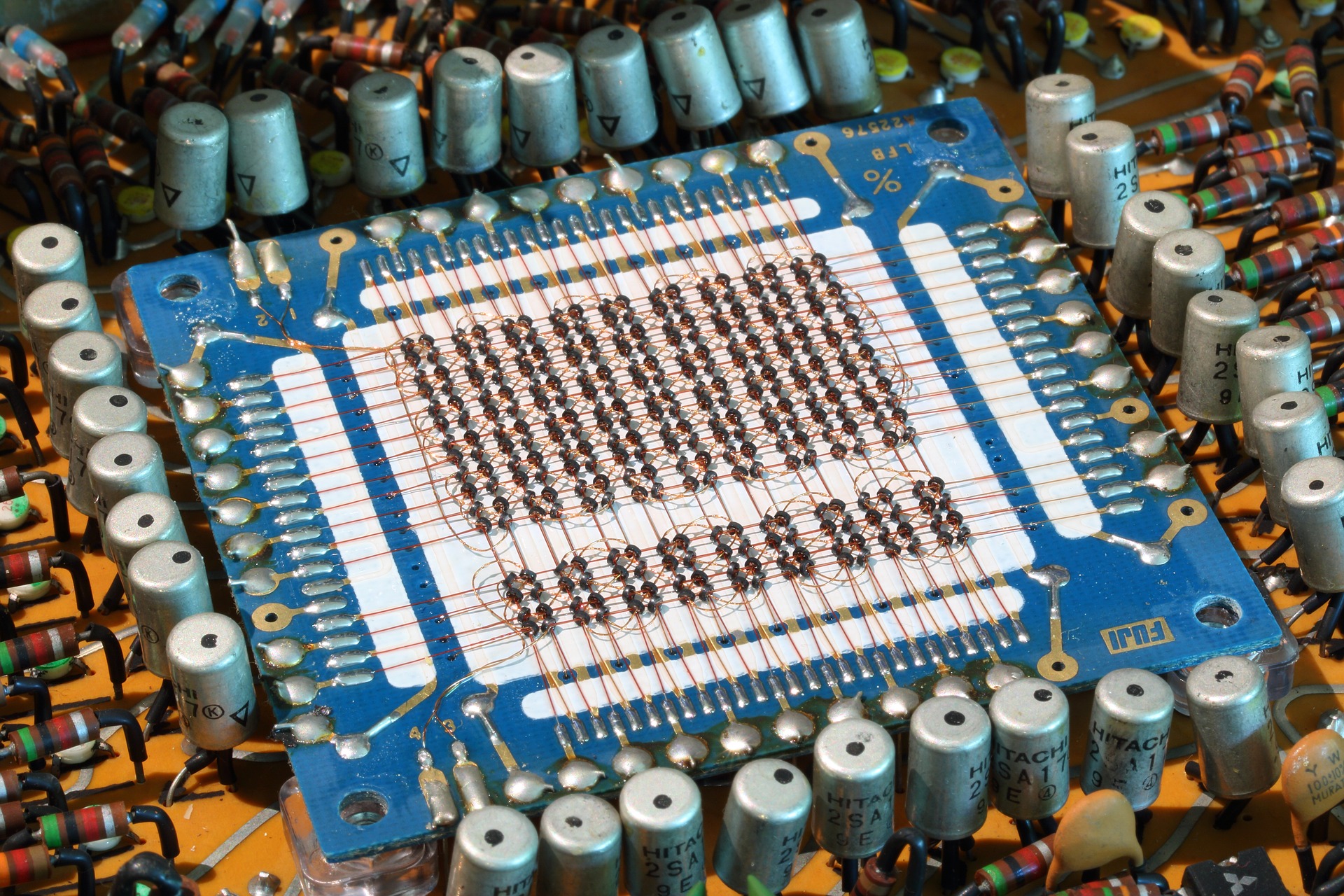

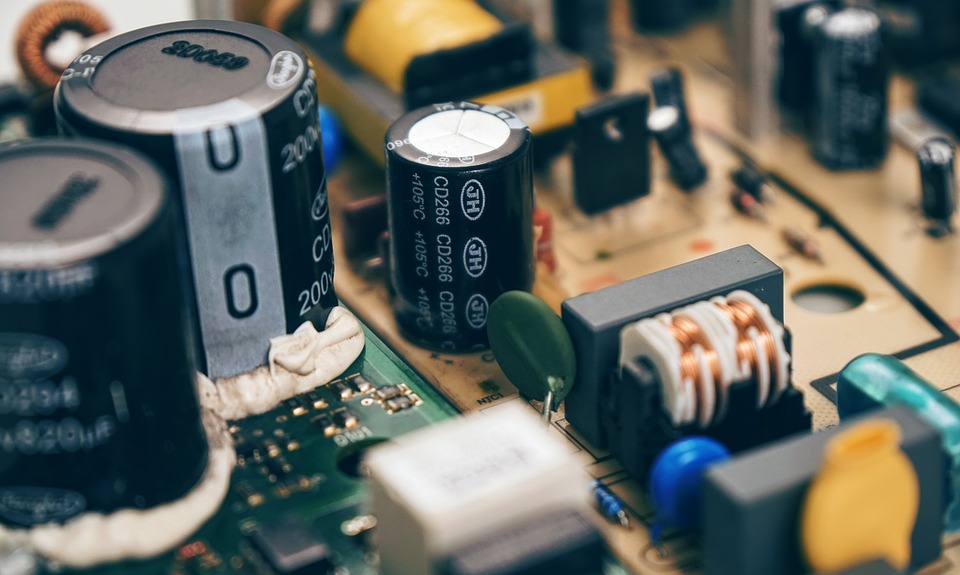

The printed circuit board (PCB) is an integral part of all electronics we use daily. Made with copper lines, fiberglass, and other components, the board is held in place using epoxy and a solder mask, which gives the board its trademark green color. A PCB with mounted components is referred to as an assembled PCB – the manufacturing is known as PCB assembly (PCBA).

The copper lines, called traces, link the components and connectors to each other electrically. Signals are run between these features, letting the board to serve its specific purpose. The board’s functions could range from complex to simple, and still a PCB’s size could be small.

Assembling a PCB is quite straightforward, comprising multiple manual and automated steps. The PCBA process begins with the most basic aspect of the board: the base. It comprises multiple layers that play a major role in the PCB’s overall functionality.