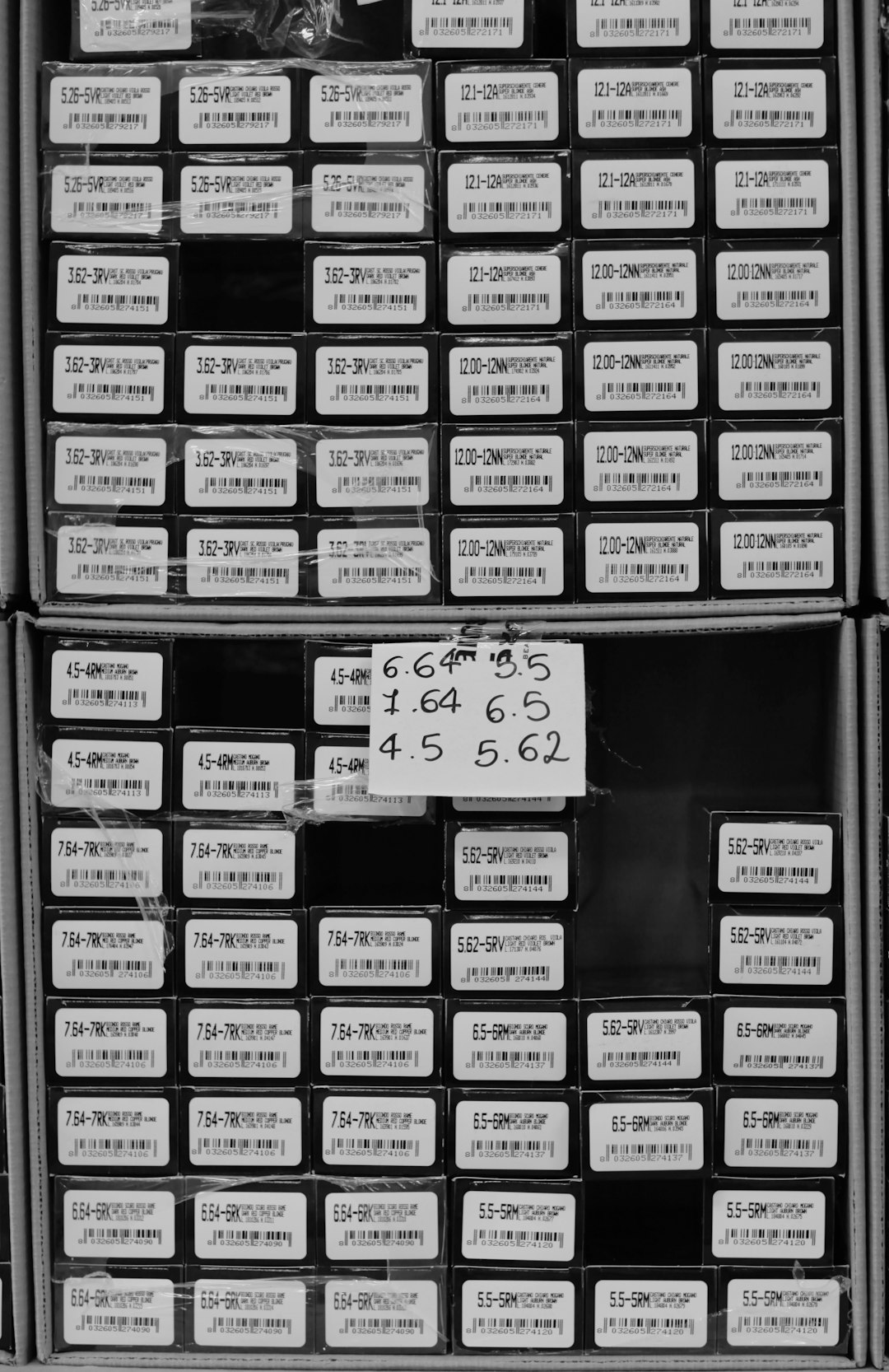

Acrylic is a unique plastic material that has a multitude of applications, especially in the engraving world. The material is available in a wide range of colours, including transparent, and can be altered to take any shape. Perspex acrylic is highly respected in the industrial sector due to its outstanding qualities. Laser cut Perspex, in particular, is ideal because it can be cut to precision, unlike other machine cut acrylics.

Why use lasers?

Apart from achieving incredible precision, laser cutting has numerous advantages to your plastic sheet. Laser projection allows the artisan to deliver beautiful artistic designs to your Perspex. It is perfect for engraving, branding, sculpture, signage marketing and etching. Lasers provide an incredibly accurate Perspex sheet with no imperfections while achieving an exceptional level of detail.

The technology can be applied to any acrylic sheet with a thickness of 25 millimetres. Another advantage of laser cutting is that the final cut requires minimal polishing.